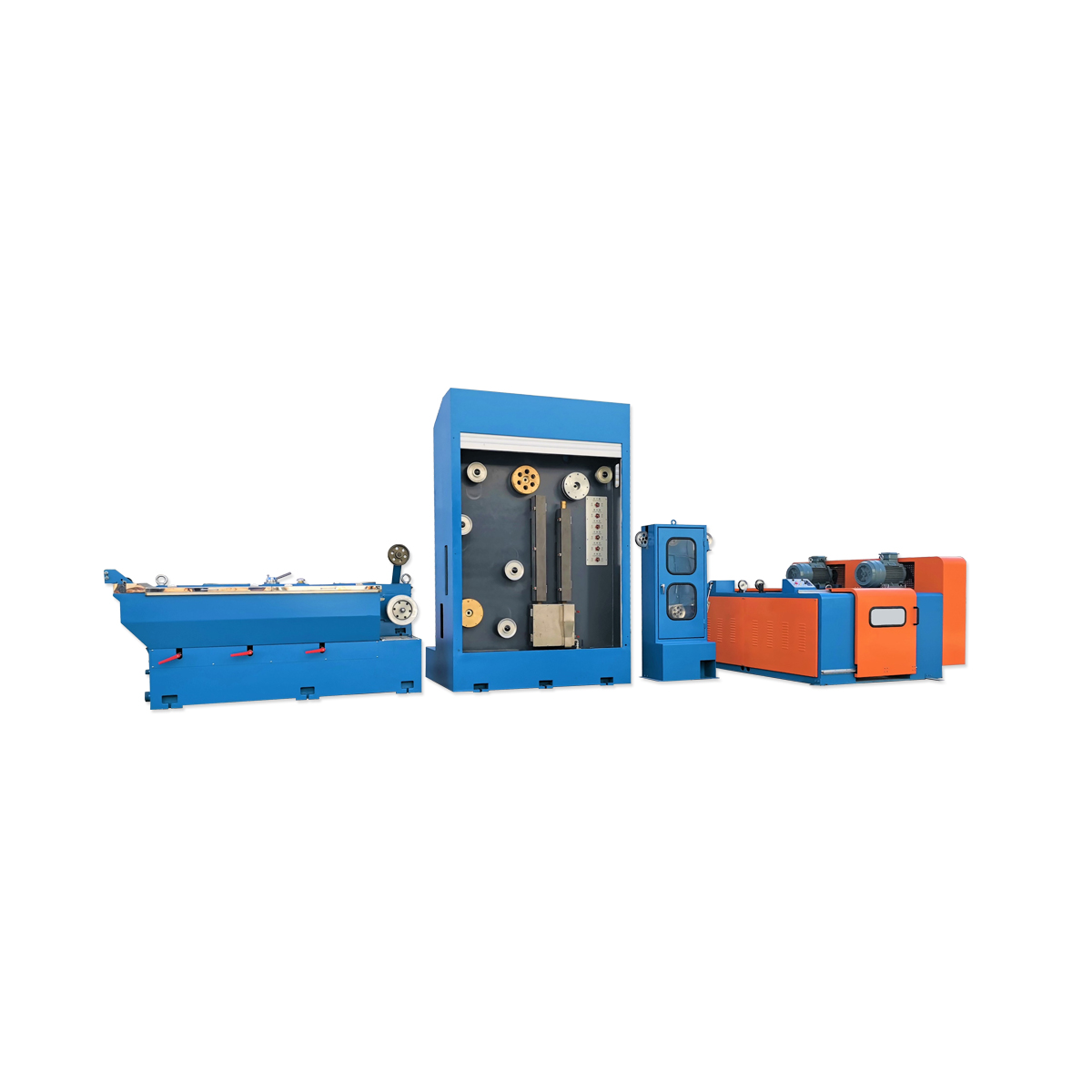

1.?The machine is capable of drawing double wires and annealing simultaneously, which significantly enhances its efficiency.

2.?It features dual drives and motors for take-up control. The drawing process is stable, with independent tension control, making the wires less prone to breakage.

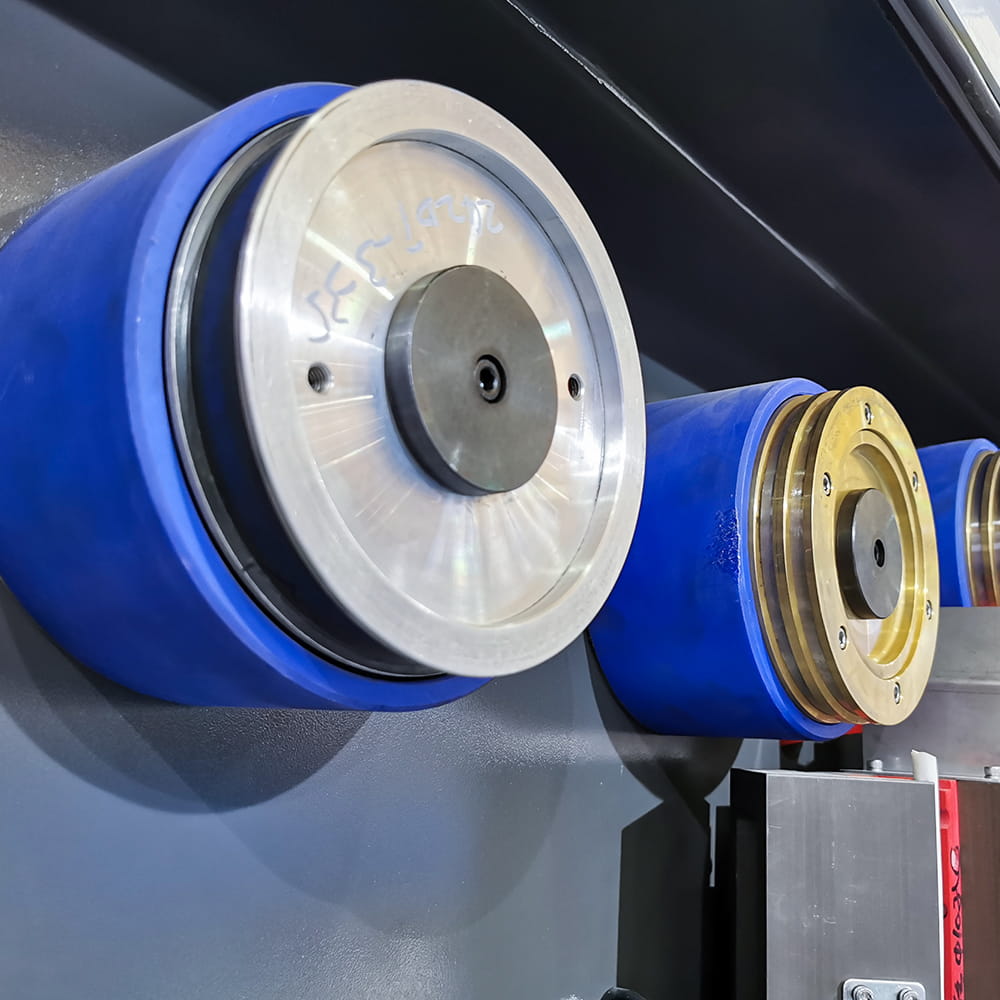

3.?Spray ceramic wire pulleys are employed, with 4 in each of the 11 layers and 1 in the final layer, arranged horizontally to facilitate more convenient wire threading.

4.?The compact machine body design maximizes the space for guiding operations. The cover in the pull drum area is a sealed stainless-steel door cover that can be manually opened, presenting a beautiful and elegant appearance.

| Model: | 24-2DT |

| Inlet diameter: | 2X1.0mm-1.6mm |

| Outlet diameter: | 2X0.19mm-0.5mm |

| Quantity of drawing dies: | 24 |

| Slip ratio of main machine: | 16% |

| Slip ratio of last die: | 8% |

| Max. Drawing speed: | 2000m/min |

| Using motor/ main motor: | 30kw |

| Usage: | Bare copper wire drawing |

| Correction system: | Automatically control |

| Annealing method: | DC three section annealing |

| Voltage: | 380V or Customized |

| Brake: | Pneumatic brake |

| Operation direction: | Right hand machine |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

中文簡體

中文簡體 русский

русский Espa?ol

Espa?ol ????

????