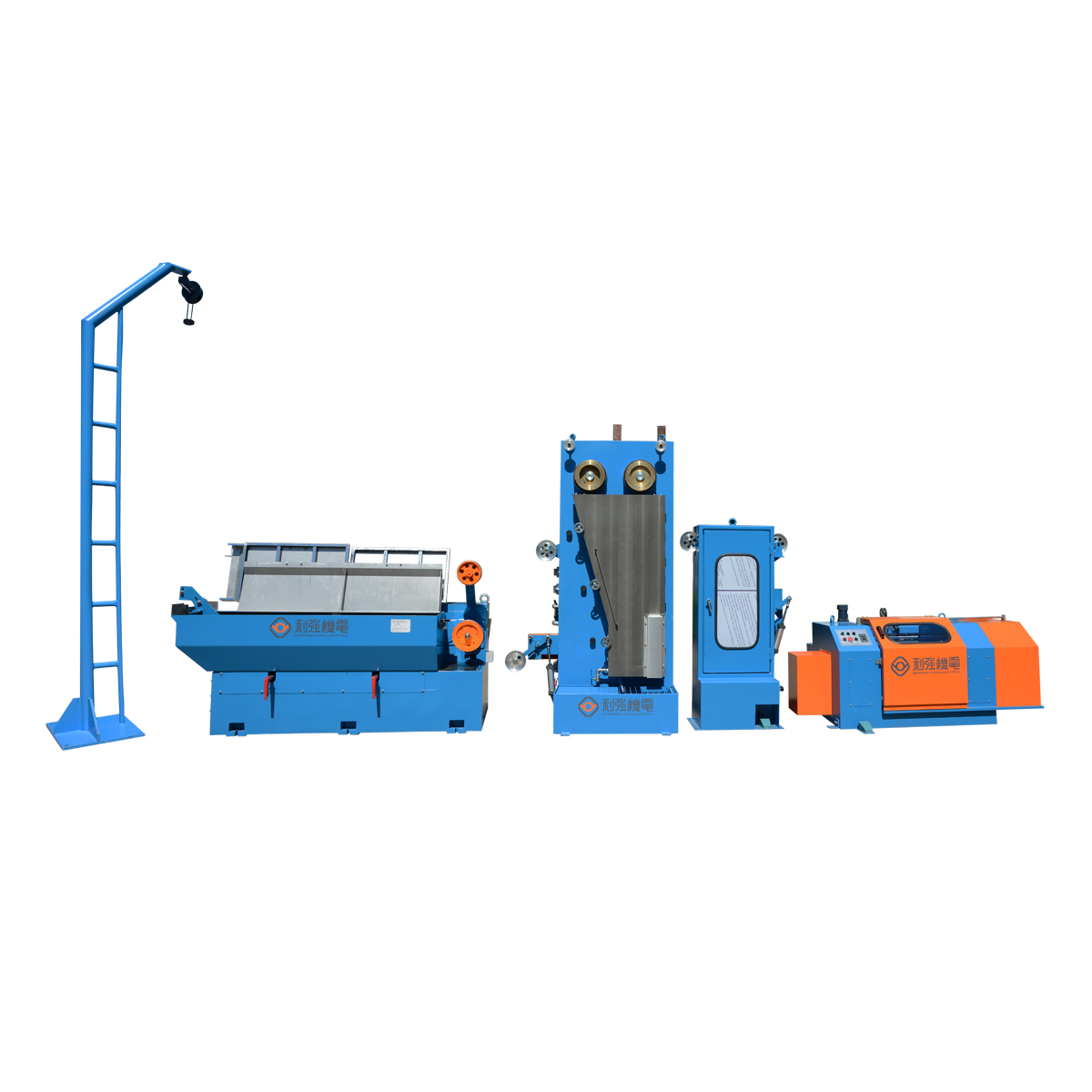

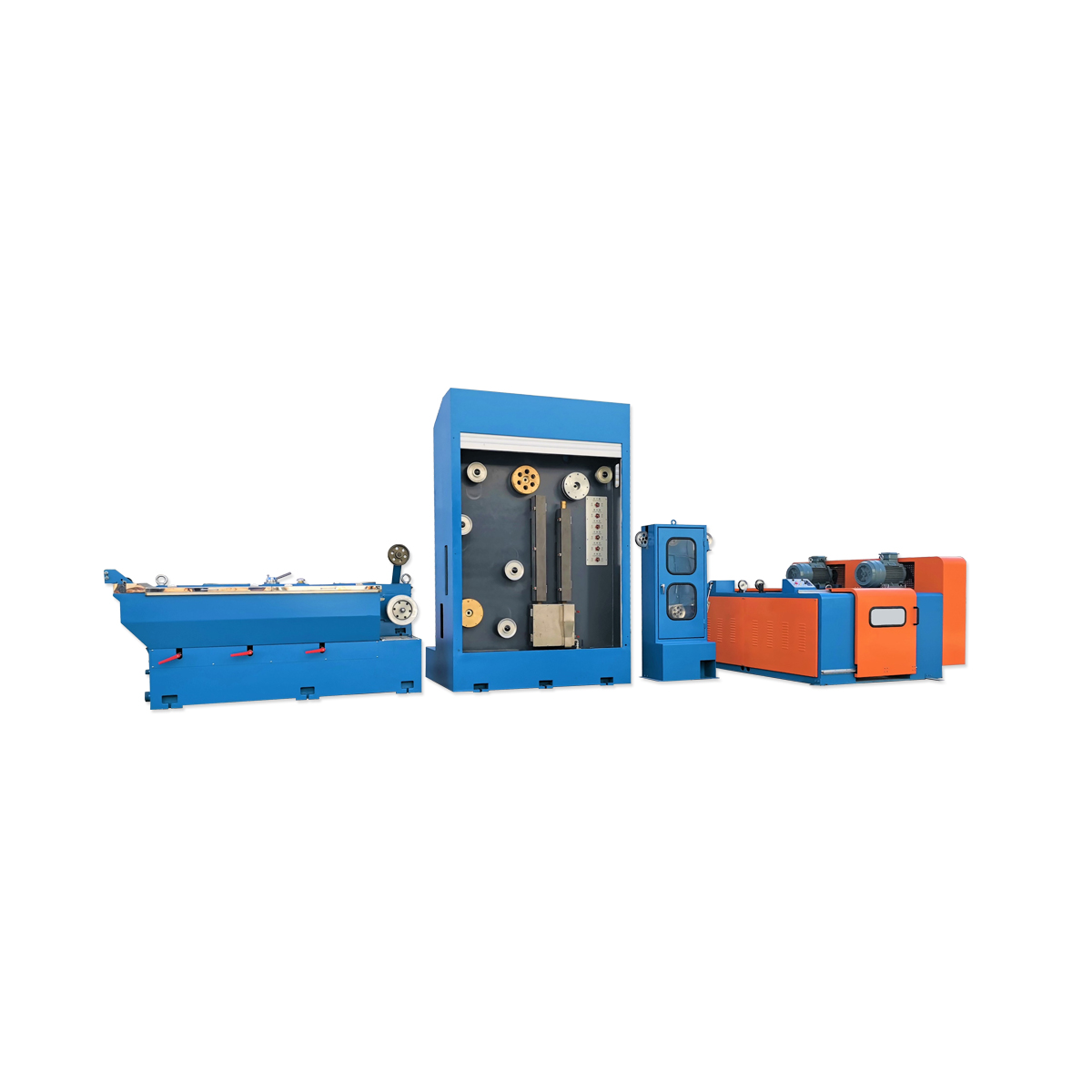

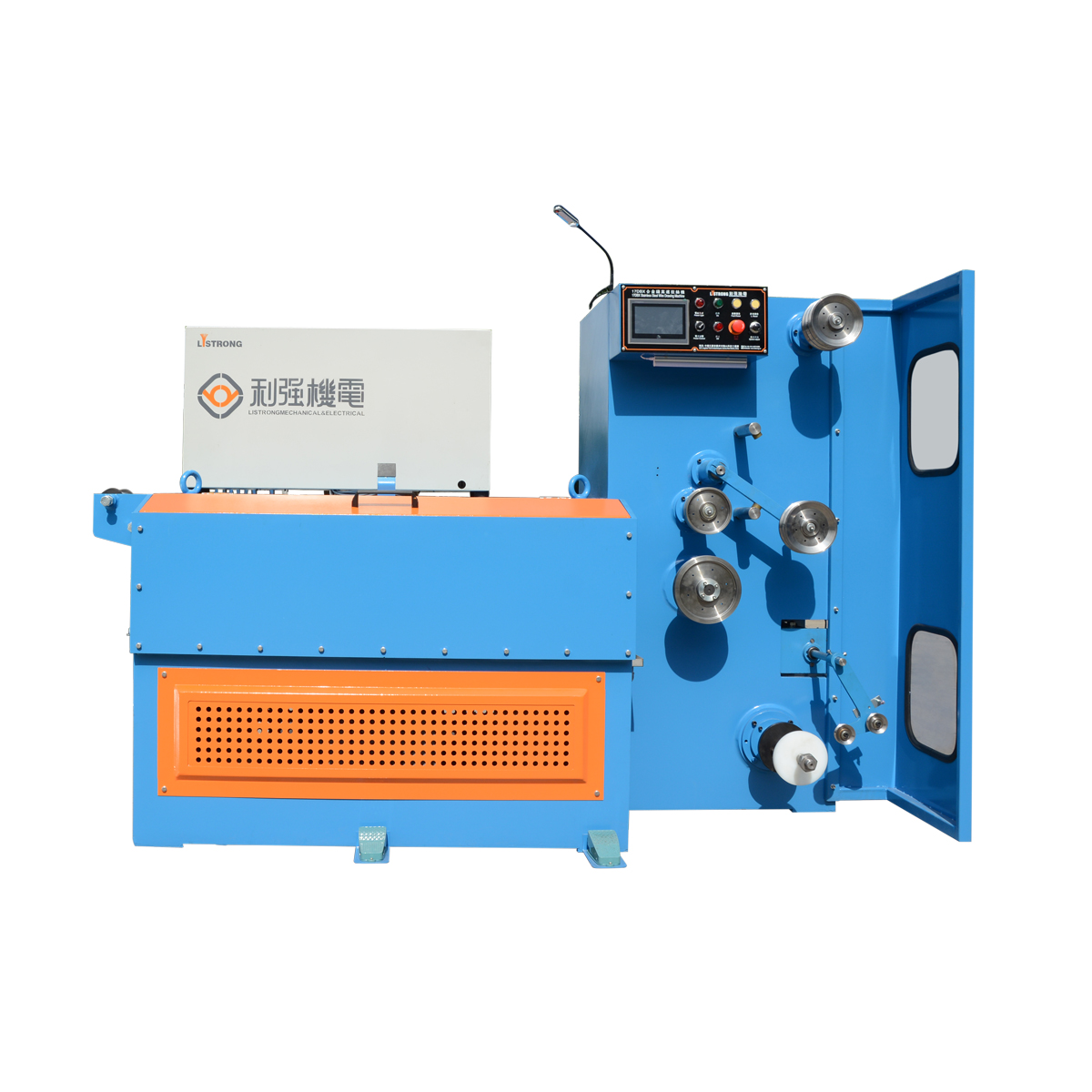

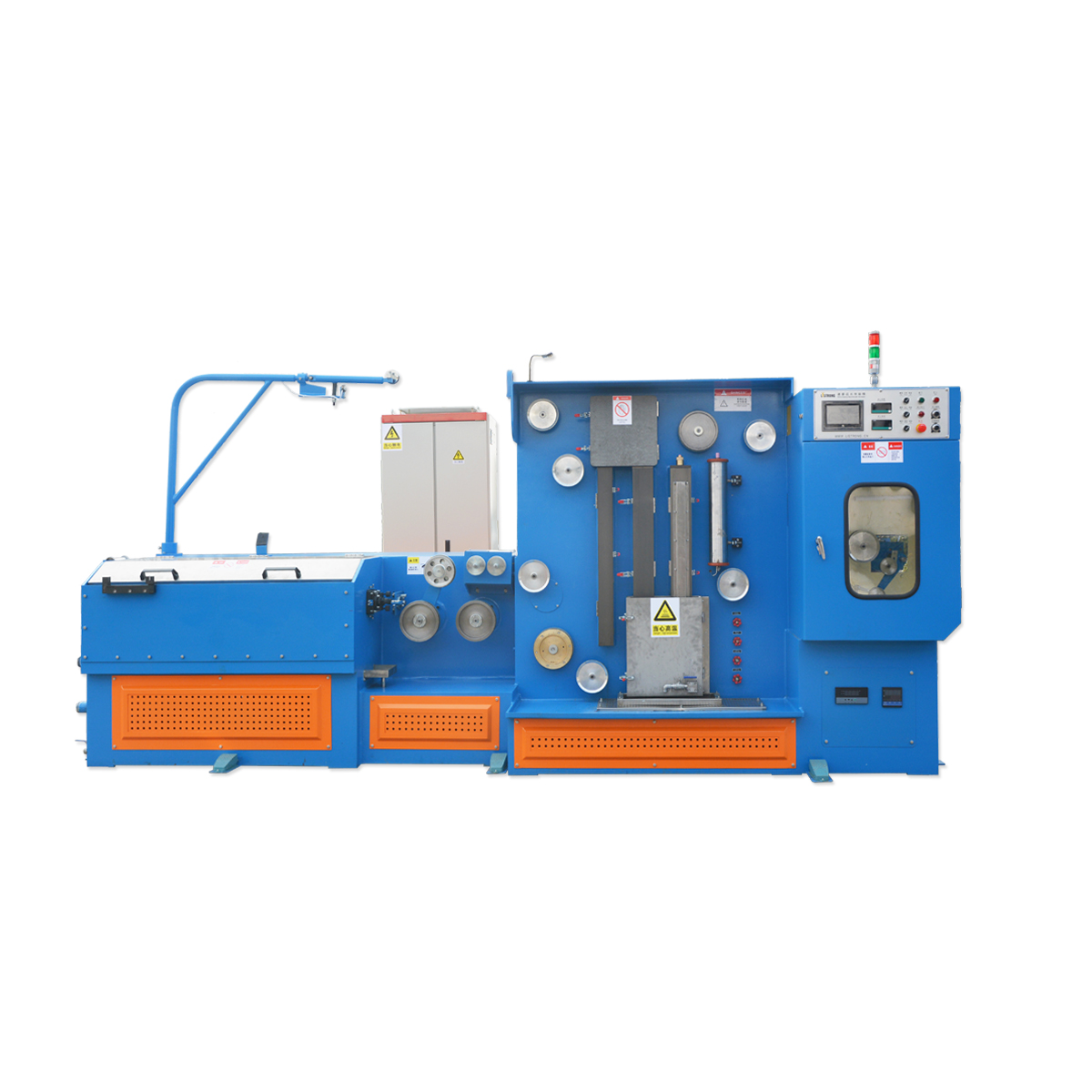

1.?Twenty - four copper wires are softened simultaneously, enhancing production output and efficiency.

2.?The machine is equipped with a uniform - temperature - distribution system, demonstrating excellent energy-saving performance.

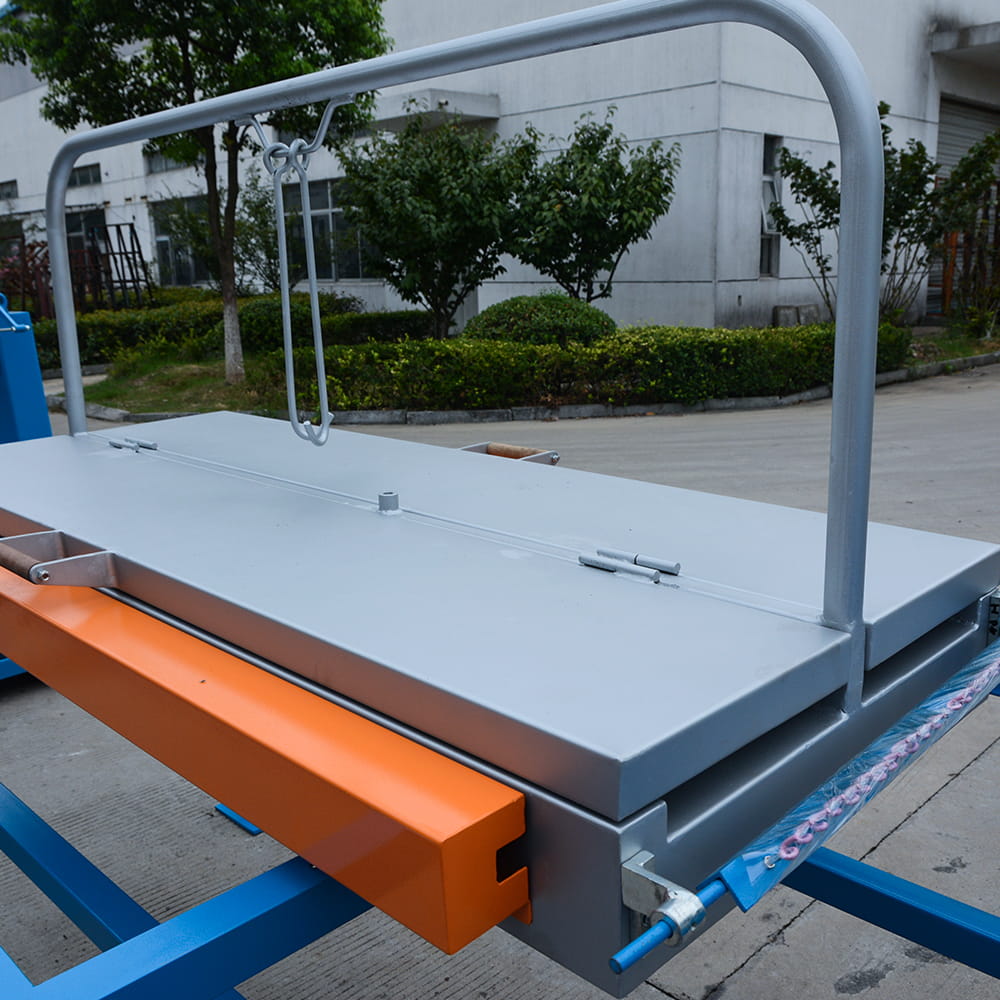

3.?An independent traversing motor is installed.

4.?The double-layer coiling design reduces the equipment's footprint.

|

Production speed |

?100MPM/MAX |

|

Pay-off spool dimension |

?Φ200mm /Max (according to customer’s requirements) |

|

Heating power of annealing furnace |

??59.4KW |

|

Roller leading |

?Double inverter and motor control; power; 2.2KW-4P*2 |

|

Wire number |

??24pcs/max. on pay-off & annealing, 20 pcs/max. on take-up machine. |

|

Take-up spools |

?DIN125, DIN160, DIN200 (according to customer’s requirements) |

|

Machine weight: |

?10000kgs |

中文簡體

中文簡體 русский

русский Espa?ol

Espa?ol ????

????